Demystifying EDA Support For ISO 26262 Tool Qualification

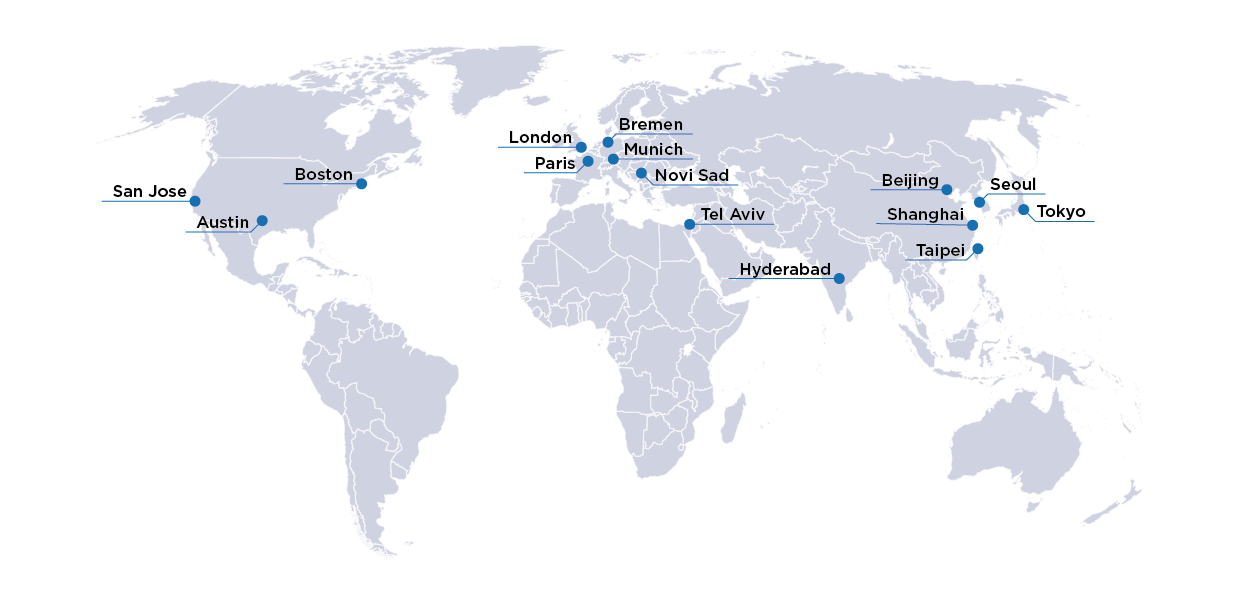

By Sergio Marchese, Semiconductor Engineering

My new, mid-size car is equipped with many advanced driver-assistance systems. To be honest, it’s taking me time to get used to some of them, as, for example, lane-centering assist that seamlessly takes control of my steering wheel. However, I cannot wait to get my hands off a fully autonomous vehicle and be able to take a nap while 7nm chips run machine learning and other artificial intelligence algorithms do the driving for me.

[…]

Over the last decade, these applications have propelled automotive electronics into the cutting-edge club once reserved for high-end smartphones and beyond. Unlike smartphone screens, though, the steering system must definitely not freeze while I am sleeping, even if unavoidable random hardware failures occur.

The ISO 26262 functional safety standard is crucial to develop complex electronic systems that provide the level of safety required by modern automotive applications.

ISO 26262 tool qualification

Safety standards must be rigorous and ISO 26262 most certainly is. Engineers use numerous software tools and there is no doubt that these tools may introduce or fail to detect errors in hardware designs. ISO 26262 does not overlook this possibility, and part 8 section 11, titled “Confidence in the use of software tools,” aims to reduce the risk of undetected tool malfunctions.

The first step is to determine the required tool confidence level (TCL), which in turn depends on tool impact (TI) and tool error detection (TD) capabilities (see Fig. 1). Most tools have impact TI2 as they can either introduce or fail to detect errors. TD indicates the confidence that tool errors will be prevented or detected. For a given TI and TD, TCL can be uniquely determined as shown in Fig. 1. For example, if tool impact is TI2 and tool error detection is TD1 (high confidence), the required confidence level is TCL1. It is worth noting that TI, TD and the resulting TCL depend on the specific use case of a tool within a project.